Pitting corrosion is one of the most insidious and localized forms of metal degradation observed in industrial materials. For those working with alloys such as the VT1000 series (a hypothetical high-performance alloy used in advanced industrial environments), understanding pitting corrosion is essential. Although this article does not present actual photos, it provides detailed descriptive examples of what pitting looks like and how practitioners interpret those visuals in real-world situations.

how it appears in photographs, what causes the specific patterns that engineers and inspectors observe, how to differentiate pitting from other surface damage, and how knowledge of these visual indicators informs material maintenance and failure prevention.

What Is Pitting Corrosion?

Pitting corrosion is a highly localized form of corrosion that leads to the formation of small holes or cavities on a metal surface. Unlike uniform corrosion that affects broad areas, pitting starts at microscopic sites and can deepen rapidly, often under crevices or deposits. Because pits can be difficult to detect early and can grow deeper faster than they widen, they are especially dangerous in load-bearing components.

In the case of VT1000, an alloy engineered for strength and oxidation resistance, pitting is not common under normal conditions — but when it does occur, it often signals an environmental or material stressor that must be addressed.

Why Photographic Examples Matter

Photographs are powerful tools in corrosion analysis because they capture the detailed morphology of degrading surfaces. Pitting pits are not uniform; they vary in shape, size, and distribution. By studying multiple photographic examples, technicians and engineers learn to recognize patterns, compare severity, and correlate visual cues with underlying causes.

Although this article does not display actual images, the description of pitting features mimics what professionals label and annotate when reviewing photos during inspections.

Typical Visual Features of Pitting on VT1000

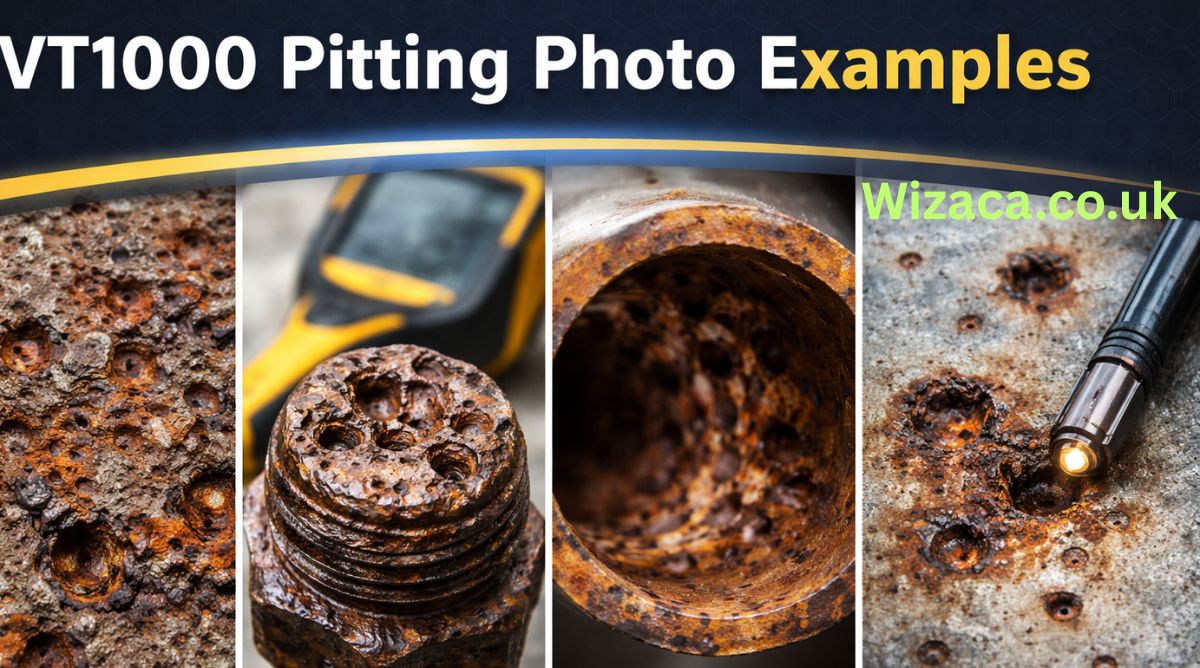

When inspecting a photograph of a VT1000 surface exhibiting pitting, several common features stand out:

Concentrated Cavities or Depressions

The most recognizable sign of pitting is the presence of distinct cavities — small but deep compared to the surrounding surface. In a photo, these look like tiny craters.

Imagine a metal panel viewed at close range, with clusters of small dimples across a few square centimeters. These pits break the surface continuity but may be narrow at the opening and extend deep below the surface.

Darkened Edges Around Pits

Pitting often leaves contrasting coloration around the pits. In VT1000 examples, the areas immediately surrounding the pit mouths can appear darker or slightly discolored compared to the untouched alloy.

On photographic examples, this contrast helps inspectors distinguish pitting from scratches, machining marks, or dents.

Varied Pit Sizes

Pitting rarely produces perfectly uniform holes. A typical photograph might show a range of pit diameters — some barely visible to the naked eye, others large enough to cast tiny shadows in directional light.

For example, in a 50-millimeter section of VT1000 surface, you might see pits ranging from 0.5 millimeters to 2 millimeters in width.

Clustered vs Distributed Patterns

In some cases, pitting appears as clusters — groups of pits in a localized zone. In other cases, pits are distributed more evenly across a surface. Photographs often reveal these patterns, and careful interpretation helps determine whether localized contaminants, design geometry, or environmental exposure contributed to the issue.

Subsurface Corrosion Indications

In advanced cases, beneath shallow pits, darker subsurface lines may show where corrosion has etched deeper channels. In photos taken at an angle, these channels sometimes catch light differently, signaling hidden damage.

Example Description: Shallow Surface Pitting

In a typical photographic example of shallow surface pitting on VT1000, the inspector may note:

- Small dimples covering a 10-square-centimeter area

- Pit depths appearing no more than 0.1 millimeters

- No visible cracking or flaking

- Darkened borders contrasting against the bright alloy surface

These features suggest early-stage pitting, often associated with surface contamination or inconsistent cleaning practices. In photographs, shallow pits create a stippled effect, like the texture on lightly sanded metal.

Example Description: Deep Localized Pits

A more severe example captured in a photo might show:

- Individual pits up to 3 millimeters deep

- Narrow pit mouths, indicating rapid undercutting

- Clustering near edges or seams

- Subsurface corrosion channels visible at pit bases

Deep pits like these are more dangerous because they can significantly reduce cross-sectional strength without obvious surface indication. In photographs, these often appear as shadowed cavities under directional lighting, providing visual depth cues.

Example Description: Pitting Under Deposits

Another common example appears in photos where contaminants or deposits mask underlying pitting:

- Surface deposits of dust or residue covering most of the alloy

- After partial removal of deposits, clusters of pits become visible

- Pits appear darker and deeper compared to surrounding clean surface

- Edges of pits may show slight buildup of deposit byproducts

These examples illustrate how real-world surfaces may hide corrosion until cleaned or exposed carefully.

Example Description: Pitting Adjacent to Weld Zones

In a photo of a welded VT1000 component, the following might be observed:

- Pits concentrated near the heat-affected zone (HAZ) of the weld

- Fewer pits on the base metal farther from the weld

- Pit shapes elongated parallel to weld seams

- Slight discoloration indicating thermal stress effects

Weld-adjacent pitting often points to residual stresses or changes in microstructure affecting corrosion resistance.

Example Description: Pitting in Moisture Accumulation Areas

Some photos show pitting in areas where moisture tends to collect:

- Low points on curved surfaces showing dense pitting

- Vertical areas with drip lines showing isolated pit trails

- Slight gradients of pit size increasing toward lower edges

These examples align with environmental exposure — prolonged contact with water or condensate encourages pitting initiation.

Distinguishing Pitting from Other Surface Damage

In many practical cases, analysts must distinguish pitting from other surface irregularities that appear in photographs. Common confusions include:

Scratches vs Pits

Scratches form linear marks, whereas pits are localized depressions with depth. In photos, scratches often show as elongated lines of uniform contrast, while pits appear as individual dots with darker centers.

Machining Marks vs Pitting

Machining marks are patterned and consistent — they follow the tooling direction. Pitting is random, with irregular spacing and inconsistent size.

Dents vs Pits

Dents result from impact and usually have smooth, broad depressions. Pits are more angular, with sharper edges at their mouths.

How Lighting Affects Pitting Photographs

Photography of pitting is strongly influenced by lighting conditions. Professionals often use directional lighting to cast shadows that reveal pit depth.

Top Lighting

Top lighting can flatten visual contrast but helps highlight surface discoloration patterns.

Side Lighting

Lighting at a low angle emphasizes depth by casting shadows inside pits. This makes them more visible and easier to measure visually.

Diffused Lighting

Soft lighting helps reduce glare on bright alloy surfaces, making subtle pits easier to distinguish from shiny reflections.

Interpretation Challenges in VT1000 Pitting Photos

VT1000, like many high-performance alloys, can reflect light strongly, making small defects hard to see in photos. Proper exposure and focus are crucial.

Inexperienced observers may misinterpret glare or surface texture as pitting. Thus technicians use controlled lighting and often take multiple photographs from different angles.

Tools Used Alongside Photos for Better Assessment

Photographs are often paired with:

- Magnified imaging to measure pit dimensions

- Profile scans to chart surface topology

- Contrast enhancement to differentiate pits from surrounding alloy

These tools help convert visual evidence into quantifiable data.

Correlating Photo Features with Failure Modes

Experienced professionals learn to correlate pit appearance with underlying causes. For example:

- Many small, shallow pits often point to uniform exposure to an aggressive environment.

- Few deep pits near welds suggest localized material vulnerability.

- Pits under deposits suggest maintenance or surface cleanliness issues.

Photographic interpretation goes beyond “what it looks like” and informs “why it happened.”

Example Scenario: Pitting from Chloride Exposure

A common real-world example comes from environments with chloride exposure (such as coastal or de-icing agents). In a described photo:

- Pits appear concentrated on horizontal surfaces

- Residue patterns consistent with salt deposits

- Higher pit density near fastener heads or joints

This pattern indicates chloride-induced localized corrosion, a common risk factor for alloys like VT1000 when protective films are compromised.

Example Scenario: Pitting from Stress Concentration

In parts under mechanical stress, such as near bends or load points, pitting photos might show:

- Elongated or irregular pit shapes

- Pit clusters aligned with stress lines

- Increased depth compared to surface area

These visual indicators suggest a combination of mechanical stress and environmental attack.

Pit Depth and Structural Implications

Photographic examples often include depth context. While shallow pits may pose little immediate risk, deeper pits reduce the effective cross-section and can act as initiation points for cracking under load.

In VT1000, engineers look at how pit depth in photos correlates with load zones. Deep pits near high-stress areas trigger more urgent inspection and mitigation.

How Photos Influence Maintenance Decisions

Photos of pitting help determine:

- Whether parts can be cleaned and reused

- Whether replacement is necessary

- If protective coatings failed

- If environmental controls need improvement

These decisions are based on visual severity and distribution, informed by photographic evidence.

Communicating Findings with Photographic Records

Photographs become part of inspection reports. Annotated examples show pit size ranges, affected zones, and comparison with standard tolerance thresholds. Clear images make communication between field technicians and design engineers more effective.

Best Practices for Taking Pitting Photos

Quality photographic documentation involves:

- Controlled lighting

- Consistent scale references

- Multiple angles

- Close-up macro views

- Background contrast to enhance visibility

These practices ensure images are useful for analysis and comparison.

Training Staff to Recognize Pitting in Photos

Workshops and training modules often include annotated photo sets showing:

- Early-stage pitting

- Advanced pitting

- Pits under deposits

- Pitting adjacent to stress points

Training improves recognition and reduces misinterpretation.

Prevention Strategies Informed by Photo Analysis

Patterns in pitting photos guide preventive strategies, such as:

- Improving surface coatings

- Enhancing cleaning routines

- Reducing exposure to chlorides

- Adding drainage to prevent moisture pooling

- Redesigning stress concentration zones

Photos provide visual evidence that directs practical action plans.

Conclusion

Pitting corrosion is a serious mode of material degradation, particularly in high-performance alloys like VT1000. Photographic examples — even when described rather than shown — help professionals identify, interpret, and respond to pitting. Understanding the visual cues associated with pit shape, depth, distribution, and context enables better decision-making.

By combining photographic interpretation with technical knowledge of material behavior, environmental exposure, and mechanical stress, engineers and technicians can anticipate problems, plan maintenance, and extend service life. Mastering how pitting appears in photos is not merely an academic exercise; it is an essential skill for ensuring safety, reliability, and performance in industrial systems.