Electronics

Yale GLP050VX TOSS Sensor: A Detailed Technical and Operational Guide

The Yale GLP050VX forklift is a well-known internal combustion counterbalance truck widely used in warehouses, manufacturing plants, logistics hubs, and outdoor material handling operations. Among its many safety and performance-related systems, the TOSS sensor plays a critical role in ensuring operational stability, load handling safety, and equipment protection. Understanding the Yale GLP050VX TOSS sensor requires examining its function, design philosophy, operational behavior, failure patterns, maintenance considerations, and long-term importance within modern forklift technology.

This article provides a comprehensive, technical, and educational explanation of the Yale GLP050VX TOSS sensor, written for operators, technicians, fleet managers, and equipment enthusiasts.

Understanding the Yale GLP050VX Forklift Platform

The Yale GLP050VX belongs to the VX series of forklifts designed to balance productivity, durability, and operator safety. This model is commonly powered by LPG and engineered to handle mid-range loads efficiently. Its design emphasizes ergonomic controls, advanced electronics, and integrated safety systems.

Modern forklifts such as the GLP050VX rely heavily on sensors to manage stability, engine performance, and operator inputs. The TOSS sensor is one of the components that supports this integrated electronic ecosystem.

What the TOSS Sensor Is

The TOSS sensor, often referred to as a stability or tilt-related sensor, is designed to monitor forklift movement, orientation, and dynamic conditions during operation. While not a single-purpose sensor, it contributes to the truck’s overall stability monitoring and safety logic.

In the Yale GLP050VX, the TOSS sensor works in coordination with the control system to detect abnormal motion patterns, load behavior, or potentially unsafe operating conditions.

Purpose of the TOSS Sensor in Forklift Operation

The primary purpose of the TOSS sensor is to reduce the risk of tipping, instability, or unsafe handling during lifting and travel. Forklifts operate in environments where uneven surfaces, sudden turns, elevated loads, and operator behavior can create dangerous situations.

The TOSS sensor supports safety by:

- Monitoring motion and orientation changes

- Feeding data to the control system

- Helping trigger protective responses

- Supporting operator alerts or system limits

This function is critical in preventing accidents that could result in injury, equipment damage, or product loss.

Design Philosophy Behind the TOSS Sensor

The design of the TOSS sensor reflects modern industrial equipment philosophy, which prioritizes prevention over reaction. Instead of relying solely on operator judgment, the system provides electronic awareness of dynamic conditions.

Key design principles include:

- Continuous monitoring rather than periodic checks

- Integration with onboard control modules

- Resistance to vibration and environmental stress

- Long-term reliability in industrial conditions

This approach ensures consistent performance throughout the forklift’s service life.

How the TOSS Sensor Functions

The TOSS sensor functions by detecting changes in motion, orientation, or stability parameters. These changes may include tilt, acceleration, deceleration, or directional shifts that exceed predefined thresholds.

When such conditions are detected, the sensor sends signals to the forklift’s electronic control system. The control system then evaluates whether corrective action is required, such as limiting certain functions or alerting the operator.

Interaction with the Forklift Control System

The Yale GLP050VX uses an integrated control architecture where sensors, controllers, and actuators work together. The TOSS sensor does not operate independently; instead, it communicates with the main control unit.

This interaction allows the forklift to:

- Adjust performance dynamically

- Enforce safety limits

- Maintain consistent handling behavior

- Support diagnostic monitoring

The sensor’s data becomes part of a broader decision-making process within the truck.

Role in Load Stability Management

Load stability is one of the most important safety factors in forklift operation. The TOSS sensor contributes by monitoring how the truck behaves under load, especially when lifting, lowering, or traveling with elevated forks.

If unstable conditions are detected, the system can respond by limiting speed, reducing hydraulic response, or signaling the operator to correct behavior.

Contribution to Tip-Over Prevention

Tip-over accidents are among the most serious forklift hazards. The TOSS sensor helps reduce this risk by identifying conditions that could lead to instability.

Factors monitored may include:

- Excessive tilt angles

- Sudden directional changes

- High-speed turns with raised loads

- Uneven ground conditions

By detecting these factors early, the forklift can take preventive measures.

Impact on Operator Safety

The presence of a TOSS sensor enhances operator safety by acting as an electronic safeguard. While operators are trained to follow best practices, human error is always a possibility.

The sensor supports safety by:

- Providing consistent monitoring

- Reducing reliance on manual judgment alone

- Encouraging smoother operating habits

- Supporting safer load handling

This contributes to a safer working environment overall.

Environmental and Operational Conditions

Forklifts operate in demanding environments that include dust, vibration, temperature variation, and moisture. The TOSS sensor is designed to function reliably under such conditions.

Its construction typically emphasizes:

- Sealed housing

- Vibration resistance

- Stable signal output

- Long operational lifespan

These characteristics are essential for industrial reliability.

Common Symptoms of TOSS Sensor Issues

When the TOSS sensor malfunctions or provides inaccurate data, the forklift may exhibit noticeable symptoms.

Common signs include:

- Unexpected performance limitations

- Warning indicators or fault codes

- Reduced travel or lift speeds

- Inconsistent handling behavior

Recognizing these symptoms early helps prevent larger issues.

Causes of TOSS Sensor Failure

Several factors can contribute to TOSS sensor failure over time.

These include:

- Physical damage from impact or vibration

- Electrical connection issues

- Sensor calibration drift

- Environmental contamination

Understanding these causes helps in preventive maintenance planning.

Diagnostic Importance of the TOSS Sensor

The TOSS sensor plays a role in forklift diagnostics by providing data used to identify abnormal conditions. When the system detects inconsistencies, it may log events or trigger alerts.

Technicians rely on this information to:

- Identify sensor-related faults

- Assess stability system performance

- Verify safe operating conditions

This diagnostic capability supports efficient maintenance.

Maintenance Considerations

Although the TOSS sensor itself typically requires minimal routine maintenance, its surrounding systems must be kept in good condition.

Best practices include:

- Regular inspection of wiring and connectors

- Ensuring secure mounting

- Protecting against contamination

- Verifying system calibration when required

Proper maintenance supports long-term reliability.

Calibration and System Accuracy

Calibration ensures that the TOSS sensor provides accurate data. Over time, mechanical wear or environmental exposure can affect sensor readings.

Calibration processes help restore accuracy by aligning sensor output with actual physical conditions. This ensures the control system responds appropriately.

Relationship with Other Safety Systems

The TOSS sensor does not work alone. It operates alongside other safety-related components, such as speed limiters, hydraulic controls, and operator presence systems.

Together, these systems create layered safety protection that reduces reliance on any single component.

Operational Benefits for Fleet Management

For fleet managers, the TOSS sensor contributes to reduced accident rates and equipment damage. This results in:

- Lower repair costs

- Reduced downtime

- Improved equipment lifespan

- Enhanced compliance with safety policies

These benefits make sensor-equipped forklifts more cost-effective over time.

Training Implications for Operators

While the TOSS sensor enhances safety, it does not replace proper training. Operators must understand how the system behaves and why certain limitations occur.

Training should emphasize:

- Smooth operation techniques

- Awareness of stability limits

- Understanding system responses

- Respecting safety warnings

This ensures cooperation between human and machine.

Comparison with Older Forklift Designs

Older forklifts often lacked advanced stability monitoring systems. Operators relied primarily on experience and caution.

Compared to these designs, the Yale GLP050VX with a TOSS sensor offers:

- Improved safety margins

- Reduced risk of sudden accidents

- More consistent performance

- Enhanced diagnostic capability

This reflects broader progress in industrial equipment technology.

Impact on Regulatory Compliance

Modern safety standards increasingly favor equipment with built-in safety systems. The TOSS sensor supports compliance with workplace safety expectations by reducing hazardous behavior.

This can be particularly important in regulated industrial environments.

Longevity and Lifecycle Role

Throughout the forklift’s lifecycle, the TOSS sensor continues to provide value by maintaining consistent safety behavior even as components age.

Its role becomes more important over time as mechanical tolerances change and operator turnover occurs.

Challenges in Sensor-Based Safety Systems

Despite their advantages, sensor-based systems introduce complexity.

Challenges include:

- Dependence on electronic components

- Need for trained technicians

- Potential for misinterpretation of warnings

However, these challenges are generally outweighed by safety benefits.

Future Evolution of Stability Sensors

The TOSS sensor represents an intermediate stage in the evolution of forklift safety technology. Future systems may include more advanced motion analysis, predictive algorithms, and adaptive controls.

These developments will further reduce accident risk and improve operational efficiency.

Best Practices for Maximizing TOSS Sensor Effectiveness

To get the most value from the TOSS sensor, organizations should:

- Maintain equipment properly

- Train operators thoroughly

- Respond promptly to warnings

- Integrate safety systems into operational policies

These practices ensure the sensor functions as intended.

Importance of System Awareness

Understanding the purpose and behavior of the TOSS sensor helps operators and technicians work with the forklift rather than against it.

System awareness reduces frustration and promotes safer habits.

Conclusion

The Yale GLP050VX TOSS sensor is a critical component that supports forklift stability, safety, and performance. By monitoring motion and orientation, it helps prevent tip-over risks, supports load stability, and enhances operator protection.

Although it operates quietly in the background, its influence is significant. The TOSS sensor reflects the shift toward smarter, safer industrial equipment that prioritizes prevention over reaction. When properly maintained and understood, it contributes to safer workplaces, longer equipment life, and more efficient material handling operations.

Electronics

Yakola V9 Reviews and Complaints

The Yakola V9 has become a topic of growing interest among drivers looking for affordable dash cams that offer high-quality video, modern features, and good reliability. As vehicle safety awareness increases, dash cams like the Yakola V9 have gained popularity for providing crucial footage during accidents, thefts, or disputes. However, as with many low-cost electronic devices, mixed reviews and complaints exist regarding its performance, build quality, and durability.

In this article, we’ll explore the Yakola V9 reviews and complaints, its specifications, benefits, and the most common issues reported by users. The goal is to help potential buyers make an informed decision before purchasing this budget-friendly dash cam.

What Is the Yakola V9?

The Yakola V9 is a compact and budget dash camera designed to record video footage while driving. It typically features dual cameras (front and rear), wide-angle lenses, loop recording, and parking monitoring. Its price range and advertised specifications position it as a good entry-level option for those who need basic protection without spending a fortune.

Dash cameras, like the Yakola V9, are small video recording devices mounted inside vehicles to continuously record the road ahead. These devices fall under the category of automotive video recorders, which have become increasingly popular since the early 2010s due to viral videos and accident evidence shared online.

The Yakola V9 stands out because it offers WiFi connectivity, HD or 2K resolution, and a compact design — all for a relatively low cost. However, whether it truly delivers what it promises depends on real-world reviews and long-term user experience.

Technical Specifications of Yakola V9

Here are the main technical features typically found in the Yakola V9 model:

- Resolution: 1080p Full HD (some versions claim up to 2K)

- Lens Angle: Around 170° wide-angle coverage

- Screen Size: 3-inch LCD display

- Storage: Supports microSD cards up to 64 GB

- Connectivity: Built-in WiFi for smartphone pairing

- Loop Recording: Automatically overwrites old footage

- G-Sensor: Detects impact and locks video files

- Parking Mode: Motion detection when the car is parked

- Night Vision: Infrared support (varies by model)

These specifications make it attractive for new dash cam users. However, the quality of these features and how they perform in real-world conditions can differ drastically from the claims on paper.

Positive Yakola V9 Reviews

Many online reviewers and users have shared positive feedback about the Yakola V9. Some key advantages mentioned across various platforms include:

1. Affordable Price

The Yakola V9 is often praised for being budget-friendly. Compared to high-end dash cams like Garmin or Nextbase, this model provides similar core features at a fraction of the cost.

2. Good Daytime Video Quality

Users report that the Yakola V9 performs well during the day, capturing clear images and license plates in proper lighting conditions.

3. Simple Installation

The camera is lightweight and easy to mount on the windshield. Its plug-and-play design allows anyone to set it up in minutes.

4. WiFi Connectivity

The WiFi feature allows users to connect their phones and view or download recordings instantly, avoiding the hassle of removing the SD card every time.

5. Loop Recording and G-Sensor

These safety features ensure that important footage during collisions or sudden movements is locked and saved automatically.

6. Compact Design

The Yakola V9 is small and discreet, meaning it doesn’t block the driver’s view or attract too much attention.

Overall, these positive aspects make the Yakola V9 appealing to casual drivers who want essential security footage without investing in an expensive system.

Common Yakola V9 Complaints

While the Yakola V9 has some impressive advantages, a fair number of users have also raised complaints and concerns. These issues are often related to build quality, overheating, and low-light performance.

1. Poor Night Vision

One of the most frequent complaints is that the Yakola V9 performs poorly at night. Despite claims of “super night vision,” users report grainy images and glare from headlights, making it difficult to read license plates in the dark.

2. Overheating Issues

Some users have experienced overheating during long drives or when parked under sunlight. Overheating can cause the camera to freeze or shut down unexpectedly.

3. App Connectivity Problems

The WiFi function, while convenient, has been reported as unreliable. Several customers say that the companion mobile app frequently disconnects or fails to recognize the camera.

4. Low Build Quality

The materials used in the Yakola V9, such as the mount and casing, are not as durable as premium dash cams. The adhesive mount may lose grip over time, especially in hot weather.

5. Limited Firmware Support

Unlike established brands, Yakola does not frequently update firmware or provide consistent technical support. Users often find themselves troubleshooting issues on their own.

6. False Motion Alerts in Parking Mode

When parking mode is active, the Yakola V9 sometimes records continuously due to minor movements like shadows or passing cars, quickly filling the SD card.

7. Inconsistent Audio Recording

A few users have complained about low microphone sensitivity or distorted audio during playback, reducing the usefulness of in-car sound recordings.

Comparing Yakola V9 to Other Dash Cams

When comparing the Yakola V9 to competitors, it performs decently for its price range. Dash cams such as the Vantrue N2 Pro or the Garmin Dash Cam Mini 2 offer better image quality and reliability but come at significantly higher costs.

The Yakola V9’s biggest strength lies in providing essential functions at an entry-level price. However, for professional drivers, taxi operators, or users who drive at night frequently, it may not meet expectations.

Tips to Avoid Yakola V9 Problems

To get the best performance from the Yakola V9, users should follow a few simple practices:

- Use a High-Endurance microSD Card – Dash cams constantly overwrite files, so using a durable memory card designed for continuous recording prevents corruption.

- Install in a Shaded Spot – Protect the camera from direct sunlight to avoid overheating.

- Update Firmware Regularly – If the manufacturer releases firmware updates, install them to fix performance bugs.

- Adjust Settings for Night Mode – Reduce exposure levels and adjust resolution to improve clarity in low light.

- Clean the Lens Frequently – A dirty lens can reduce image sharpness, especially during nighttime recording.

- Use a Stable Mount – Replace or reinforce the adhesive mount if it becomes loose.

By following these steps, many of the common complaints about the Yakola V9 can be minimized or avoided entirely.

User Satisfaction Overview

Overall, the Yakola V9 receives mixed reviews. Many users appreciate its affordability and basic functionality, while others feel disappointed by its durability and low-light performance. On average, it performs well for casual use but struggles under demanding conditions like hot climates or continuous operation.

The satisfaction rate tends to depend on expectations — those who purchase it knowing it’s a budget dash cam are often pleased, while those expecting premium-level performance are left dissatisfied.

Should You Buy the Yakola V9?

The Yakola V9 is best suited for:

- Budget-conscious drivers

- Occasional city drivers

- Users wanting simple front and rear recording

It’s not ideal for:

- Professional drivers or rideshare operators

- Users who frequently drive at night

- Those requiring top-tier video stability and app performance

If your goal is basic road safety coverage during daytime drives, the Yakola V9 can be a solid investment. However, if you want professional-grade clarity, consistent app connectivity, and long-term reliability, you may want to consider mid-range or premium dash cams.

Final Thoughts on Yakola V9 Reviews and Complaints

The Yakola V9 offers a good mix of affordability and features but isn’t free from shortcomings. Positive reviews highlight its simplicity, good daylight video, and value for money. On the other hand, complaints revolve around low-light recording, overheating, weak mounting, and unreliable WiFi connectivity.

As with most low-cost electronics, user satisfaction depends on realistic expectations. When installed correctly and used under moderate conditions, the Yakola V9 performs reasonably well and provides reliable front-and-rear footage for everyday driving needs.

If you’re looking for an entry-level dash cam that covers the basics without costing a fortune, the Yakola V9 deserves consideration. But if you require long-term durability, high-resolution night footage, or robust app control, investing in a higher-tier dash cam might be the smarter choice.

Electronics

Yakola V9 Reviews and Complaints

The Yakola V9 has become a topic of growing interest among drivers looking for affordable dash cams that offer high-quality video, modern features, and good reliability. As vehicle safety awareness increases, dash cams like the Yakola V9 have gained popularity for providing crucial footage during accidents, thefts, or disputes. However, as with many low-cost electronic devices, mixed reviews and complaints exist regarding its performance, build quality, and durability.

In this article, we’ll explore the Yakola V9 reviews and complaints, its specifications, benefits, and the most common issues reported by users. The goal is to help potential buyers make an informed decision before purchasing this budget-friendly dash cam.

What Is the Yakola V9?

The Yakola V9 is a compact and budget dash camera designed to record video footage while driving. It typically features dual cameras (front and rear), wide-angle lenses, loop recording, and parking monitoring. Its price range and advertised specifications position it as a good entry-level option for those who need basic protection without spending a fortune.

Dash cameras, like the Yakola V9, are small video recording devices mounted inside vehicles to continuously record the road ahead. These devices fall under the category of automotive video recorders, which have become increasingly popular since the early 2010s due to viral videos and accident evidence shared online.

The Yakola V9 stands out because it offers WiFi connectivity, HD or 2K resolution, and a compact design — all for a relatively low cost. However, whether it truly delivers what it promises depends on real-world reviews and long-term user experience.

Technical Specifications of Yakola V9

Here are the main technical features typically found in the Yakola V9 model:

- Resolution: 1080p Full HD (some versions claim up to 2K)

- Lens Angle: Around 170° wide-angle coverage

- Screen Size: 3-inch LCD display

- Storage: Supports microSD cards up to 64 GB

- Connectivity: Built-in WiFi for smartphone pairing

- Loop Recording: Automatically overwrites old footage

- G-Sensor: Detects impact and locks video files

- Parking Mode: Motion detection when the car is parked

- Night Vision: Infrared support (varies by model)

These specifications make it attractive for new dash cam users. However, the quality of these features and how they perform in real-world conditions can differ drastically from the claims on paper.

Positive Yakola V9 Reviews

Many online reviewers and users have shared positive feedback about the Yakola V9. Some key advantages mentioned across various platforms include:

1. Affordable Price

The Yakola V9 is often praised for being budget-friendly. Compared to high-end dash cams like Garmin or Nextbase, this model provides similar core features at a fraction of the cost.

2. Good Daytime Video Quality

Users report that the Yakola V9 performs well during the day, capturing clear images and license plates in proper lighting conditions.

3. Simple Installation

The camera is lightweight and easy to mount on the windshield. Its plug-and-play design allows anyone to set it up in minutes.

4. WiFi Connectivity

The WiFi feature allows users to connect their phones and view or download recordings instantly, avoiding the hassle of removing the SD card every time.

5. Loop Recording and G-Sensor

These safety features ensure that important footage during collisions or sudden movements is locked and saved automatically.

6. Compact Design

The Yakola V9 is small and discreet, meaning it doesn’t block the driver’s view or attract too much attention.

Overall, these positive aspects make the Yakola V9 appealing to casual drivers who want essential security footage without investing in an expensive system.

Common Yakola V9 Complaints

While the Yakola V9 has some impressive advantages, a fair number of users have also raised complaints and concerns. These issues are often related to build quality, overheating, and low-light performance.

1. Poor Night Vision

One of the most frequent complaints is that the Yakola V9 performs poorly at night. Despite claims of “super night vision,” users report grainy images and glare from headlights, making it difficult to read license plates in the dark.

2. Overheating Issues

Some users have experienced overheating during long drives or when parked under sunlight. Overheating can cause the camera to freeze or shut down unexpectedly.

3. App Connectivity Problems

The WiFi function, while convenient, has been reported as unreliable. Several customers say that the companion mobile app frequently disconnects or fails to recognize the camera.

4. Low Build Quality

The materials used in the Yakola V9, such as the mount and casing, are not as durable as premium dash cams. The adhesive mount may lose grip over time, especially in hot weather.

5. Limited Firmware Support

Unlike established brands, Yakola does not frequently update firmware or provide consistent technical support. Users often find themselves troubleshooting issues on their own.

6. False Motion Alerts in Parking Mode

When parking mode is active, the Yakola V9 sometimes records continuously due to minor movements like shadows or passing cars, quickly filling the SD card.

7. Inconsistent Audio Recording

A few users have complained about low microphone sensitivity or distorted audio during playback, reducing the usefulness of in-car sound recordings.

Comparing Yakola V9 to Other Dash Cams

When comparing the Yakola V9 to competitors, it performs decently for its price range. Dash cams such as the Vantrue N2 Pro or the Garmin Dash Cam Mini 2 offer better image quality and reliability but come at significantly higher costs.

The Yakola V9’s biggest strength lies in providing essential functions at an entry-level price. However, for professional drivers, taxi operators, or users who drive at night frequently, it may not meet expectations.

Tips to Avoid Yakola V9 Problems

To get the best performance from the Yakola V9, users should follow a few simple practices:

- Use a High-Endurance microSD Card – Dash cams constantly overwrite files, so using a durable memory card designed for continuous recording prevents corruption.

- Install in a Shaded Spot – Protect the camera from direct sunlight to avoid overheating.

- Update Firmware Regularly – If the manufacturer releases firmware updates, install them to fix performance bugs.

- Adjust Settings for Night Mode – Reduce exposure levels and adjust resolution to improve clarity in low light.

- Clean the Lens Frequently – A dirty lens can reduce image sharpness, especially during nighttime recording.

- Use a Stable Mount – Replace or reinforce the adhesive mount if it becomes loose.

By following these steps, many of the common complaints about the Yakola V9 can be minimized or avoided entirely.

User Satisfaction Overview

Overall, the Yakola V9 receives mixed reviews. Many users appreciate its affordability and basic functionality, while others feel disappointed by its durability and low-light performance. On average, it performs well for casual use but struggles under demanding conditions like hot climates or continuous operation.

The satisfaction rate tends to depend on expectations — those who purchase it knowing it’s a budget dash cam are often pleased, while those expecting premium-level performance are left dissatisfied.

Should You Buy the Yakola V9?

The Yakola V9 is best suited for:

- Budget-conscious drivers

- Occasional city drivers

- Users wanting simple front and rear recording

It’s not ideal for:

- Professional drivers or rideshare operators

- Users who frequently drive at night

- Those requiring top-tier video stability and app performance

If your goal is basic road safety coverage during daytime drives, the Yakola V9 can be a solid investment. However, if you want professional-grade clarity, consistent app connectivity, and long-term reliability, you may want to consider mid-range or premium dash cams.

Final Thoughts on Yakola V9 Reviews and Complaints

The Yakola V9 offers a good mix of affordability and features but isn’t free from shortcomings. Positive reviews highlight its simplicity, good daylight video, and value for money. On the other hand, complaints revolve around low-light recording, overheating, weak mounting, and unreliable WiFi connectivity.

As with most low-cost electronics, user satisfaction depends on realistic expectations. When installed correctly and used under moderate conditions, the Yakola V9 performs reasonably well and provides reliable front-and-rear footage for everyday driving needs.

If you’re looking for an entry-level dash cam that covers the basics without costing a fortune, the Yakola V9 deserves consideration. But if you require long-term durability, high-resolution night footage, or robust app control, investing in a higher-tier dash cam might be the smarter choice.

-

Home Improvement2 weeks ago

Home Improvement2 weeks agoHow to Switch Out HZ311 Thermostat for Ecobee Premium Thermostat

-

Gaming2 weeks ago

Gaming2 weeks agoHow to Sign Up on ETSGamevent

-

Technology2 weeks ago

Technology2 weeks agoHow to Use CPT Upgrade in gem5: Complete Step-by-Step Guide

-

Technology2 weeks ago

Technology2 weeks agoHow to Tell a Bad Plate on Flex Printing

-

Technology2 weeks ago

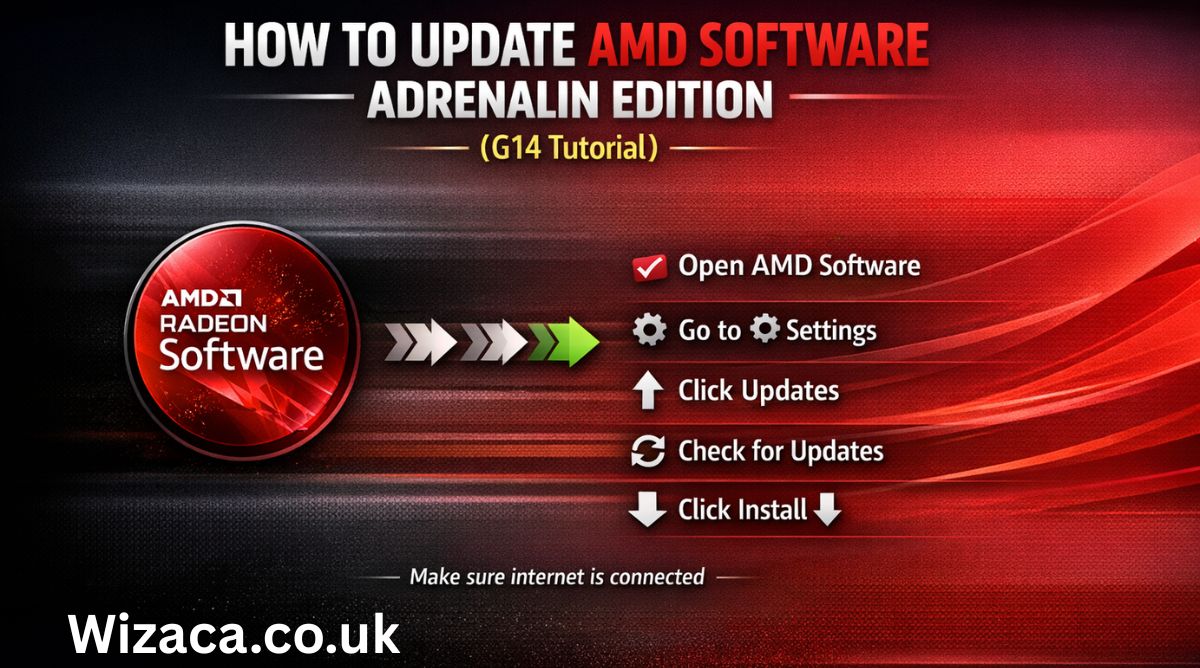

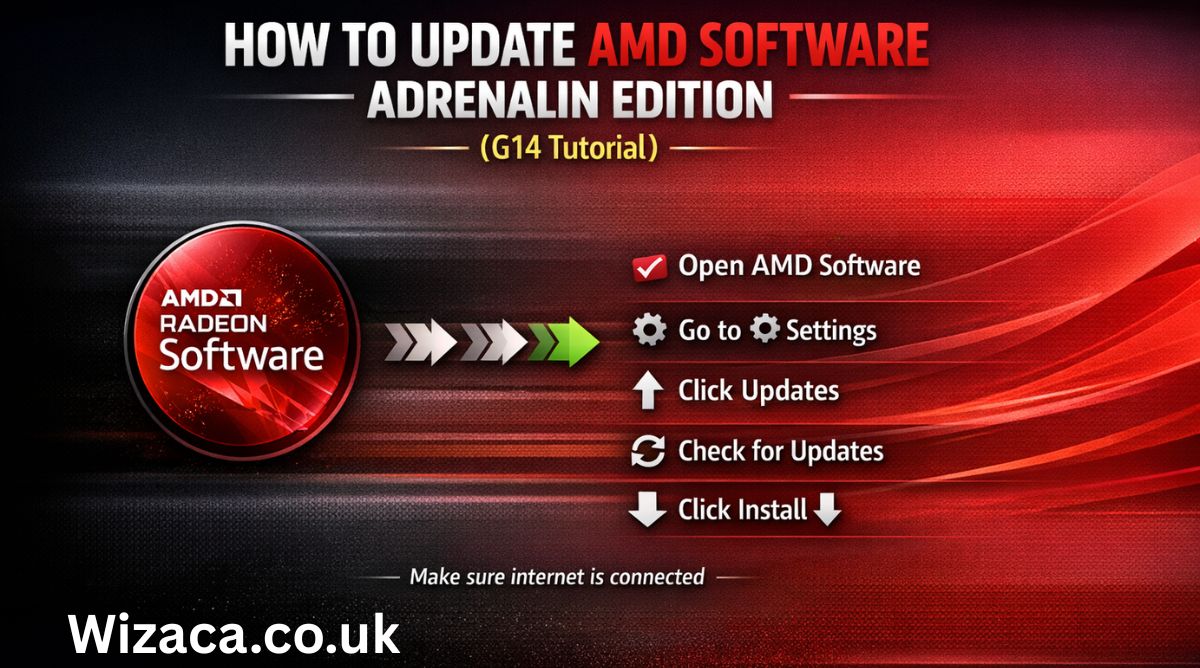

Technology2 weeks agoHow to Update AMD Software Adrenalin Edition G14

-

Technology3 hours ago

Technology3 hours agoHow to Set Honuras Time Zone on a WR20BAR G-Shock